Water is directly linked with spiritual values, with respect to mankind and living beings towards nature. Water is also firmly linked with health. According to the estimate of World Health Organization (WHO), 80% of all diseases approximately 25 million deaths per year in the developing and under developing countries are caused by contaminated water.

Water forms an essential part of every human being. Since it is a human necessity it makes best sense to do business. As a normal human being requires an average of 2-3 liters of water every day and world population is more than one billion (growing at 2-3% annually) the business opportunity is enormous and the potential is largely untapped.

The packaged drinking water industry is estimated to be a whopping business. It has grown at a rate of 38-40% annually over the past many years. Initially bottled water brands like the French manufactured Damone were promoted at clubs, fitness centers, cinema theatres, department stores, malls, ice-cream parlours, cafes and retail sports outlets, besides restaurants, hotels and supermarkets with a price tag of 70/- for 1 litre bottle. Other brands later began pitching for the larger middle class and lower middle class markets.

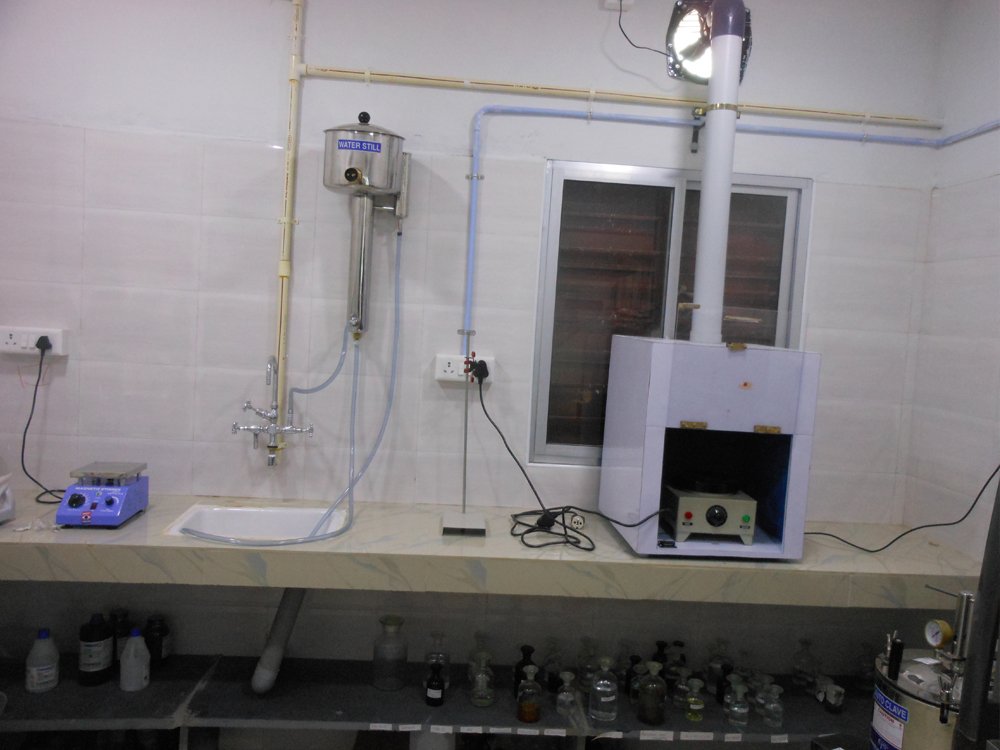

The packaged drinking water processing raw water is taken from source using pump which is well protected to avoid contamination. Then the raw water is stored in raw water tank. Raw water tank is covered with reinforced cement concrete whereas inner walls and floor of the tank is completely tiled. Water is passed into pipe line provided with electronic dosing system with disinfectant and its concentration and contact time may vary depend on the raw water quality to electromotive force to preliminary disinfection of raw water, then passed through dual media filter system or pressure sand filtration system using raw water pump to remove microbial bio-film, suspended solids, turbidity and solid particles. From dual media filter system or pressure sand filtration system the water is then passed through activated carbon filtration system to remove colour, odour, toxic elements and pesticides. The outlet water from the activated carbon filter system is passed through micron filtration system. The pre-treated raw water is dosed with anti-scaling agents before entering into reverse osmosis system to prevent scaling of reverse osmosis membranes using electronic system. The pre-filtered water is passed through reverse osmosis system with the help of pressure booster pump. The treated water from is said to be product water and rest of the water through reject outlet is said to be reject water. pH, electrical conductivity and total dissolved solids of the output water is maintained by pH, electrical conductivity and total dissolved solids monitoring arrangement. The pH of the products is maintained by dosing with pH booster if required (Food Grade) using electronic dosing system if required. The product water is passed through spring technology or degasification system, ultra violet disinfection system then collected in a clean, sterile and completely closed Stainless steel tanks and then ozone disinfection using ozone generator cupped with oxygen concentrator. From the stainless steel tank the water is pumped by using SS pump to post pleated micron filtration system (0.45 micron and 0.22 micron). From the post micron filtration system the water is taken completely closed air conditioned room and entries and exit of the room are provided with air curtain to product PET container filling, packaging labelling and batch coding, inspection lamp arrangements with the system and also taken to PE flexible pouch filling system. The filled PET containers are stored in storage area. From a batch, sample is drawn and subjected to physical and chemical and microbiological examination with respect to the scheme of testing and inspection (STI) as per the requirements of IS14543:2004 has been revised as IS 14543:2016 using prescribed standard test method as per IS or ISO or APHA or ASTM., then the finished product proceeded for despatch with respect to in-house analytical report.